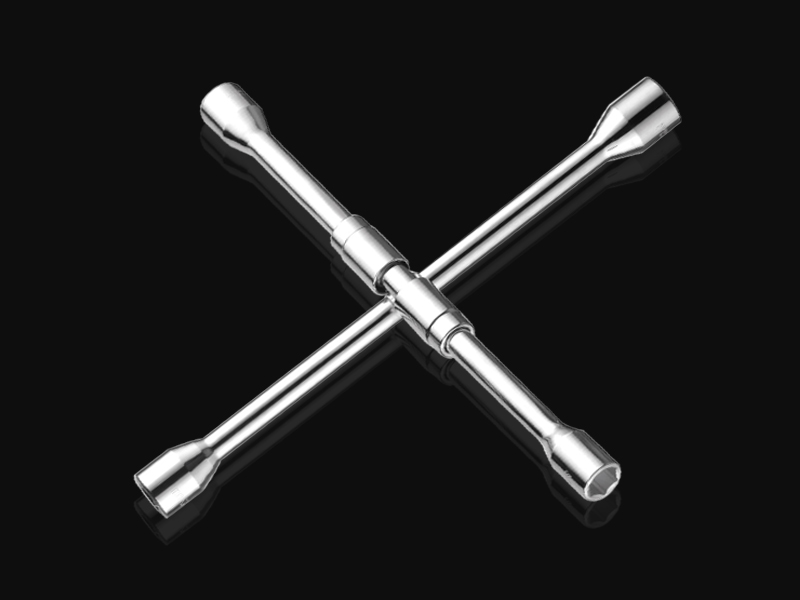

The socket Across wrench is specially used to detect th […]

The socket Across wrench is specially used to detect the tightening torque value of the connection between the steel connecting sleeve and the steel connecting wire head. Scope of application of torque wrench for steel connection sleeve: This product is suitable for testing the tightening torque value of steel connection with diameter of Φ12-Φ40MM. Technical indicators of torque wrench for steel bar connecting sleeve: daily error of indication/repetition error of indication is less than or equal to 0.5%.

Rebar connection sleeve torque wrench specifications: the length of the wrench arm is 600mm. The torque value setting range is 70~370N.M.Torque wrench operation method: the new wrench has been verified when leaving the factory, has a product certificate, and the torque value is set at the lowest position. Before use, according to the tightening torque required for the connection between the rebar joint and the rebar connecting sleeve, set the scale value of the moving scale on the wrench to the corresponding position, that is, use a special wrench to twist the lead screw to make the rebar on the moving scale Align the specification scale with the engraved line on the wrench handle, then steadily bite the jaws of the connected steel bar or sleeve, firmly hold the handle of the wrench, and apply force clockwise.

When you hear a "click" sound, you can stop adding At this time, the tightening torque value of the reinforcement joint has reached the specified requirements.Adjust the accuracy of the wrench: insert a special key into the end hole of the tail and turn it clockwise to increase the torque value, and turn it counterclockwise to decrease the torque value. Precautions for using torque wrench: 1. Pay attention to waterproof, mud, sand and other debris entering the handle of the wrench. The torque wrench is strictly prohibited to be used as a hammer. 2. When using the wrench, the pliers head should be flat, the force should be even, and no excessive force or impact should be applied.

When you hear the "click" sound of the torque wrench, immediately stop pulling the wrench to avoid damage to the force measurement part of the wrench. 4 The wrench is strictly prohibited to be used when the setting position is zero, because there is no sound when the force is added in this state When the signal is sent out, it is easy to overload and damage the wrench. 5. When the wrench is not suitable for a long time, the wrench scale value should be set at the zero position to avoid fatigue and inaccuracy of the force measurement element. 6. During use, if the wrench has no sound signal, stop using it immediately and perform maintenance. The repaired wrench needs to be calibrated and can be used only after the calibration is qualified.